The TMS-2000 comes with user-focused data acquisition software for consistent wafer thickness measurement, analysis and data output.

Wafer thickness mapping system, TMS-2000, that can measure flatness with 1nm precision.

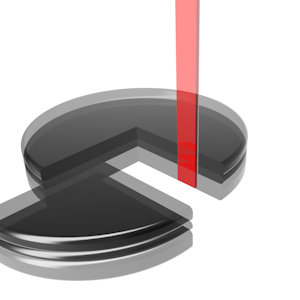

The new system from Santec, the TMS-2000, brings a new dynamic to high accuracy sub-nanometer mapping of semiconductor wafer thickness. Utilizing a novel laser scanning method, not previously used in the industry for wafer mapping, the TMS-2000 offers several benefits to the industry; accurate thickness measurements that are insensitive to temperature variations, a single system to measure not just Si single layers but also power semiconductors such as SiC and GaN, as well as multilayer wafers like SOI, at a cost point that is attractive for widespread deployment in production. As semiconductor devices reduce in size, the tolerances for the lithography processes become finer, raising the importance of high accuracy in wafer thickness and site flatness measurements. For non-contact, sub-nanometer precision measurements the industry has relied on heterodyne interference or Fizeau fringe analysis systems that have several drawbacks for universal adoption. These current solutions require front and back wafer illumination, are sensitive to temperature variations and vibrations, and are high in complexity and cost. The Santec TMS-2000 addresses all those concerns found with the present solutions.

1. High Repeatability

High-accuracy measurement using interferometric detection technique (1nm precision)

2. Industry Standard Parameters

Analysis of Global (GFLR, GFLD, GBIR), Site (SFQR, SFQD, SBIR), Edge (ESFQR) possible

3. High Environmental Resistance

No temperature control or vibration countermeasures are required due to environmental durability

4. Compact Size

Small form factor suitable for multiple applications

5. High Speed

Spiral Scanning (High speed, high density)

The TMS-2000 comes with user-focused data acquisition software for consistent wafer thickness measurement, analysis and data output.

Flatness parameters compliant with SEMI standards can be statistically analyzed and the data can be output in industry-accepted formats.

Reveal higher-order deviations from intended form. Discover complex surface defects through automatic normalization with Zernike polynomials.

In-plane profiling, even for wafers with mm-order warpage. Gravity correction; true wafer shape is obtained from front and back of wafer.

High sensitivity enables detection of front and back surfaces of highly absorbing wafers.

Highly doped Si-wafers may prove challenging for other non-contact thickness mapping systems, not so for the TMS-2000.

Measure thickness uniformity before the coarse grinding stage and beyond.

Map wafers with different top and bottom finishes, from 4 to 12 inches in diameter.

Polarization effects are compensated, and a high signal is achieved for ultra-low-reflectance interfaces.

Examples include Silicon Carbide (SiC) for power electronics or Lithium Niobate (LiNbO3) for telecoms.

Layers from microns to hundreds of microns thick, all mapped simultaneously.

Applications include manufacture of Silicon-on-insulator (SOI) wafers and micro-electromechanical systems (MEMS).

Diverse thin films down to a thickness of 4μm, measured to a precision of 1nm.

Monitor back-grinding of silicon substrate, or thin films as in Surface Acoustic Wave (SAW) devices.

We tailor embedded wafer mapping hardware and software for integrated systems and production tools.

We support design integration for robotic handling and controlled mini environments.